Pre-cut: fast, predictable, and usually cheaper per ton

Pre-cut (stock) carbon steel is like grabbing a ready-made meal — it’s quick and priced competitively because mills produce standard sizes in volume. If your design tolerates standard thicknesses and dimensions, pre-cut reduces lead time, paperwork, and tooling setup costs. For small runs or prototypes, it often wins on upfront price and convenience.

Custom-cut: less waste, lower downstream cost

Custom-cutting tailors material to your exact part sizes, which can dramatically cut scrap and reduce machining or finishing time. Think of custom cut as a tailored suit: it costs more up front, but you save on alterations later. For high-volume parts or tight-tolerance assemblies, custom cutting frequently lowers total landed cost despite a higher unit price.

How to compare: total landed cost beats sticker price

Don’t decide on price per kilogram alone. Compare: material cost + processing (cutting, slitting, edging) + scrap disposal + labor + storage + lead-time risk. If pre-cut causes extra machining or waste, that “cheap” option can be more expensive in the long run. Conversely, custom cuts can be overkill for simple builds and inflate cost unnecessarily.

Practical tips to pick the right route

Run a quick cost model: estimate scrap percentage and secondary processing hours for each option. Ask suppliers for sample runs or nesting layouts to see real waste rates. Negotiate partial custom runs (mix of stock + cut-to-size) to balance speed and efficiency.

At Dongte Metal, we help buyers model total cost and choose the mix of pre-cut and custom-cut steel that saves money and keeps production smooth.

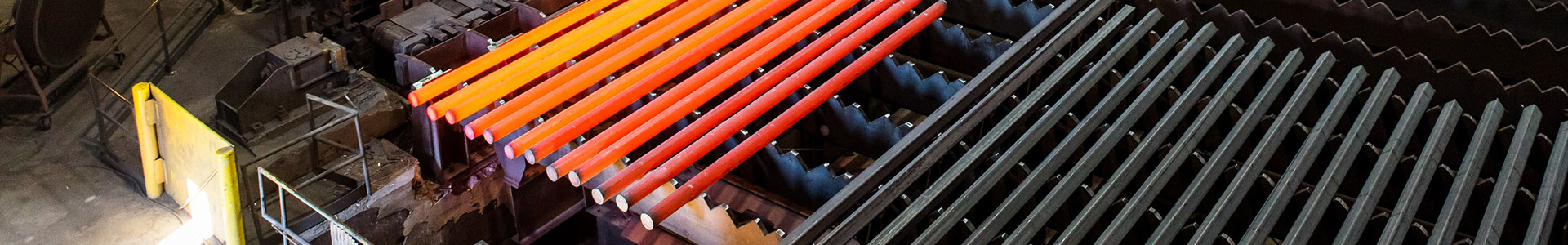

At Dongte, we have Steel Plate, Steel Coil, Steel Pipe, Profiles, Steel Rebar, Wire Rod, Round Bar, Flat Bar, Dcutile Iron Pipe.

Contact Dongte Metal today to get a tailored cost comparison for your next order.