18

2025

-

07

The Journey of Steel: From Furnace to Finished Product

From Earth to Furnace: It All Starts with Raw Power

Steel’s story begins deep in the earth, where iron ore, coal, and limestone are extracted and brought to life in a blast furnace. It’s like baking a cake—only at 1,500°C! These ingredients are melted together into molten iron. DONGTE STEEL uses advanced smelting technology to make this process ultra-efficient, minimizing waste and maximizing purity.

Refining the Recipe: Turning Iron into Steel

Next up? The molten iron gets purified in a converter, where oxygen is blown through to burn off impurities. At this point, it officially becomes steel. This stage is all about chemistry and control—getting the right mix of strength, flexibility, and toughness. With its cutting-edge refining methods, DONGTE STEEL ensures each batch meets exact specifications for diverse applications.

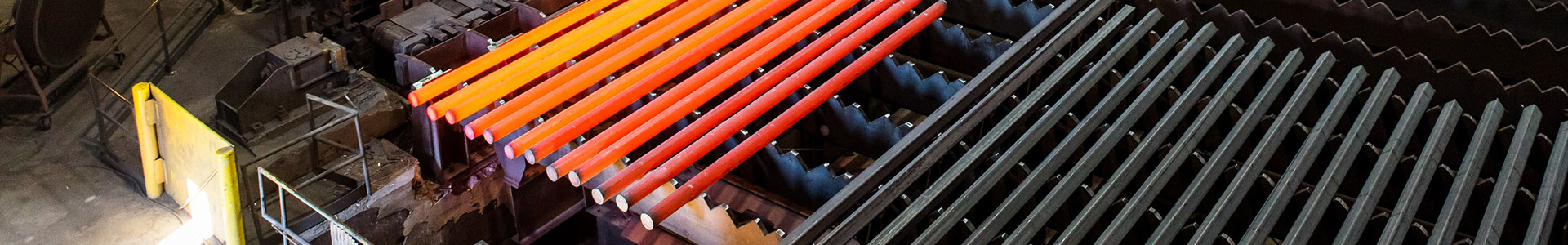

Casting, Rolling, and Shaping: Where Form Meets Function

Once refined, the steel is cast into slabs, blooms, or billets—think of them as steel “dough” ready to be shaped. Through hot rolling and cold rolling, the steel takes its final form: sheets, coils, bars, and more. DONGTE STEEL delivers a wide range of finished products, tailored to industries like construction, automotive, and machinery.

Quality Control and Delivery: The Final Touch

Before anything leaves the factory, each product is tested, inspected, and stamped with quality assurance. DONGTE doesn’t just ship steel—they deliver reliability, consistency, and trust in every ton.

Final Thoughts

Steel’s journey is long, hot, and technical—but the result? Strong, dependable materials that shape the modern world. With DONGTE STEEL, you’re not just buying steel—you’re investing in expertise forged through every step of the journey.

In our company, we have steel beam, flat bar, channel steel, angle bar, round bar, steel rebar, wire rod, carbon steel, stainless steel, ductile iron pipe.