18

2025

-

04

Cold Rolling vs. Hot Rolling: What’s the Difference & Why DONGTE Steel Has Both Covered

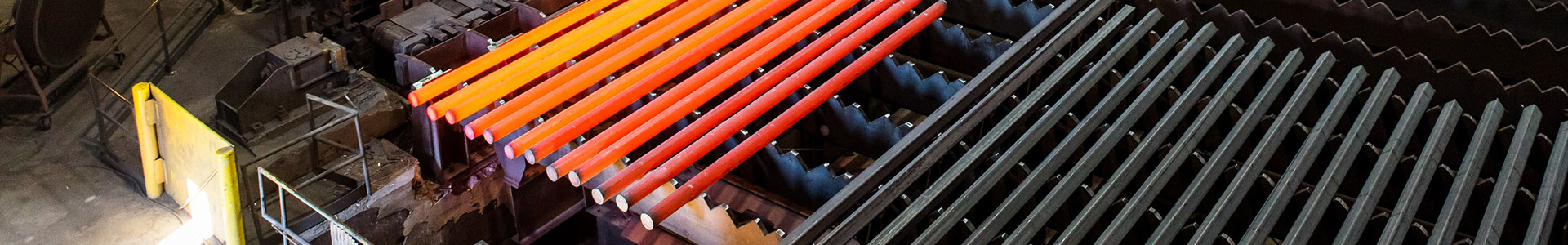

Hot Rolling: Built for Big Jobs

Hot rolling is kind of like baking bread—you work with high heat to get things shaped just right. Steel is rolled at extremely high temperatures (above 1,700°F), making it easy to mold into large shapes like beams, rails, and heavy sheets.

-

Applications: Great for construction, shipbuilding, and industrial machinery. If precision isn’t the top priority but strength and scale are, hot-rolled steel is your go-to.

Cold Rolling: Smooth, Sharp, and Precise

Cold rolling, on the other hand, is more like fine-tuning. After the steel cools, it’s rolled again at room temperature. This gives it a smooth finish, tighter tolerances, and improved strength.

-

Applications: Ideal for products that require a polished look and precision—think home appliances, car panels, and metal furniture. If appearance and accuracy matter, cold-rolled is king.

How DONGTE Steel Rolls with the Best

At DONGTE Steel, we offer both cold-rolled and hot-rolled steel—manufactured with care, tested for quality, and delivered with reliable service. Whether you’re building big or working on high-end finishes, we’ve got the right material to fit your specs.

From bulk orders to customized cuts, we help you get exactly what you need—no stress, just steel that performs.

Steel That Works as Hard as You Do

Choosing between cold-rolled and hot-rolled steel shouldn’t be a guessing game. At DONGTE Steel, we make it simple—quality steel, expert support, and solutions that roll with your business.

CONTACT

Tel : +86 15315550509

WhatsApp : +86 15315550509

Wechat : +86 15315550509

Email : sales07@zgdtsteel.com

All Rights Reserved © 2023 Dongte (China) Metal Products Sales Co., LTD. SEO