06

2024

-

11

Differences in the Process of Angle Steel and H-beam Steel

Angle steel is a common metal material. Due to its strong bearing capacity, corrosion resistance and stable quality, it is widely used in construction, machinery, ships, railways, roads and bridges. In today's society, angle steel has become an indispensable industrial material. There are significant differences in the process between angle steel and H-beam steel, which are mainly reflected in the production method, processing process and application characteristics.

1. Production method

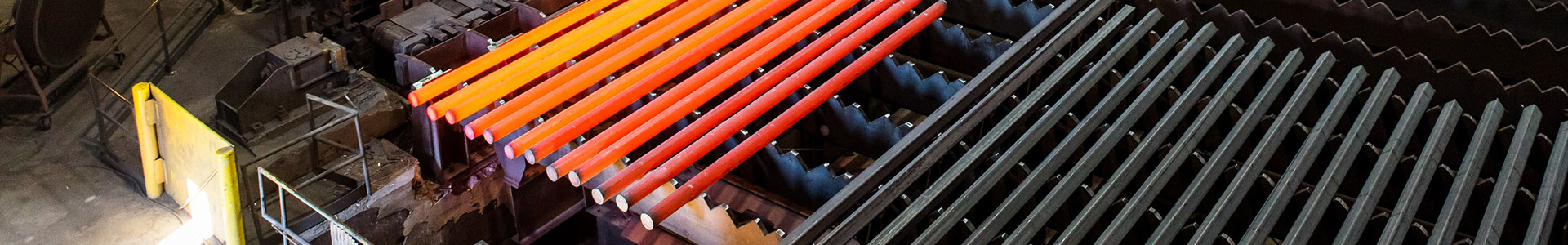

Angle steel: There are two main production methods for angle steel: hot rolling and cold drawing. Hot-rolled angle steel is to heat the steel billet to a certain temperature, roll it on a roller, and press it into a steel of a specified shape. This production method can ensure that the surface quality of the angle steel is good, the size is accurate, and the quality is stable. Cold drawing is to first cool the heated steel billet to room temperature, and then roll it into strands through continuous cold drawing. Compared with hot rolling, this method of production has the advantages of fast forming and simple process, but it is more likely to produce surface cracks and is not suitable for producing angle steel that withstands strong forces.

H-beam: The production process of H-beam mainly includes the steps of smelting, rolling, finishing and inspection. First, the molten steel is smelted in an electric furnace or converter, and the impurities and gases are removed by refining. Then, the molten steel is poured into the rolling mill for rolling to form the initial shape of the H-beam. Next, the rolled steel is subjected to finishing treatments such as straightening, trimming and cutting to obtain qualified H-beam. Finally, the finished steel is inspected for quality to ensure that the size, shape and surface quality meet the standards.

2. Processing technology

Angle steel: The processing technology of angle steel generally undergoes shearing, cutting, punching, drilling, welding and other processes. Among them, the most basic processing technology is shearing. Shearing is the process of processing long strip angle steel into corresponding lengths. For smaller angle steels, cutting and other processes can be used. The processing process is simple and the processing accuracy is easier to control. For larger angle steels, punching, drilling and other processes are required to meet the requirements of different projects.

H-beam: The processing of H-beam is relatively complex, mainly involving its unique cross-sectional shape and performance requirements. During the rolling process, parameters such as rolling temperature, rolling force and rolling speed need to be strictly controlled to ensure that the cross-sectional shape and performance of the H-beam meet the design requirements. In addition, the cutting, welding and other processing processes of H-beam also need to be adjusted and optimized according to its special cross-sectional shape.